Endless Manufacturing Possibilities

Create custom parts at a low cost, in a short amount of time. Whether it’s designing and creating a unique part from scratch or customizing an existing part design to create parts that fit specific requirements, the ability to develop and produce complex objects without the need for specific tooling offers a high level of flexibility.

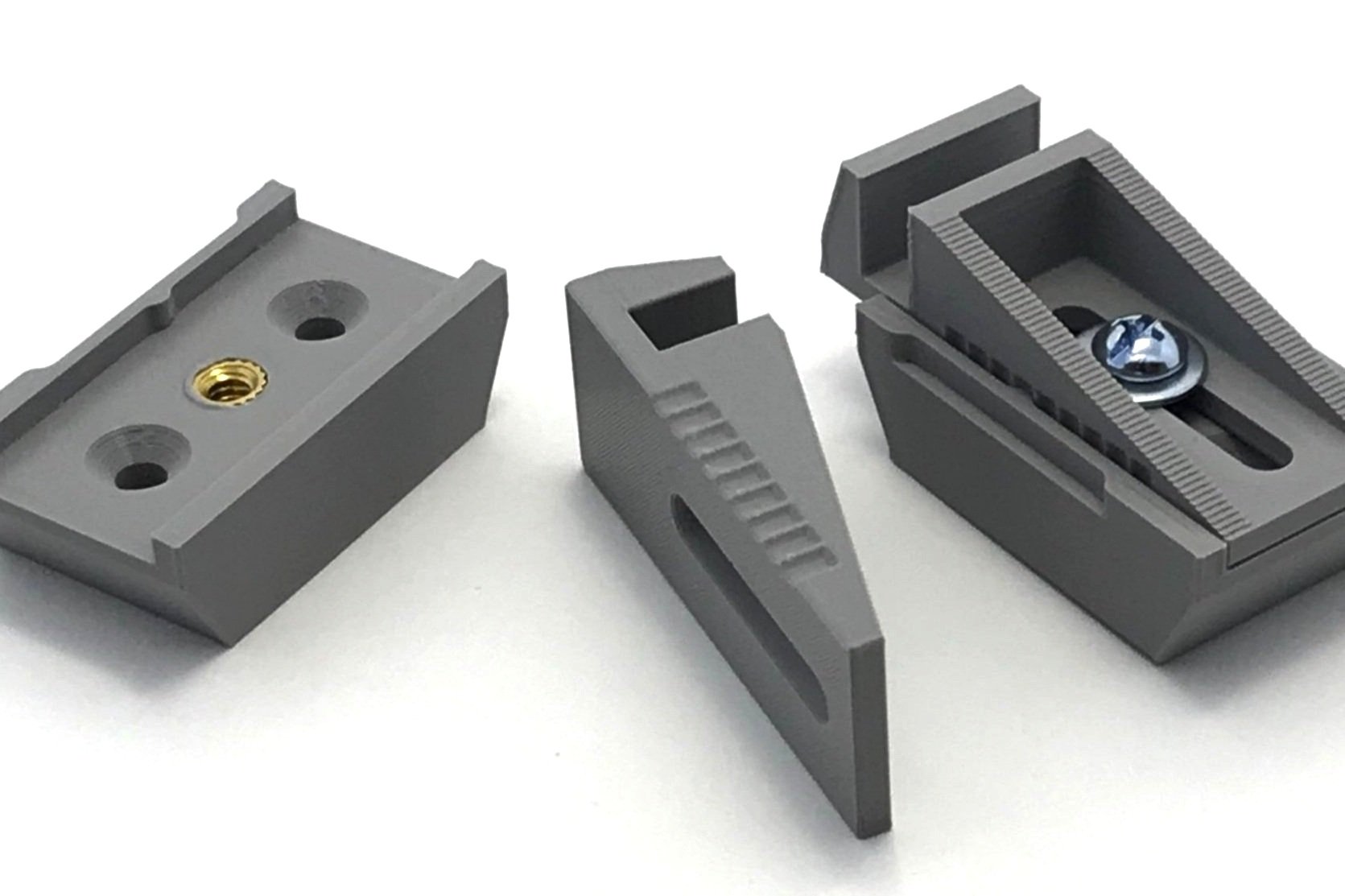

Custom brackets for all types of applications are a great fit for 3D printing. Create brackets with specific shapes, sizes, angles, and hole patterns. The brackets shown here are reinforced with screws for increased strength where it’s needed.

Sliding brackets can be designed to move along flat surfaces or curved surfaces of any diameter. Threaded inserts are heat set in place to add metallic thread performance to a plastic part.

A custom configuration of an adjustable structural pipe fitting.

These pivot mount flanges incorporate steel sleeves at their pivot locations for increased strength and wear resistance.

Create custom flanges with specific shapes, inside/outside diameters, and hole patterns.

Custom snap fit hardware for quickly and easily assembling and disassembling parts without the need for tools.

These custom brackets incorporate indexed movement along a fixed range of motion, allowing them to be adjusted in controlled increments.

A custom pivoting bracket with an orbiting movement - this part is adjustable and locks in place with set screws.

Design structural pipe fittings to hold specific pipe diameters at specific angles.

Create custom enclosures with dimensions and features tailored to spec.

Custom pillow blocks designed to fit custom spaces.